English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

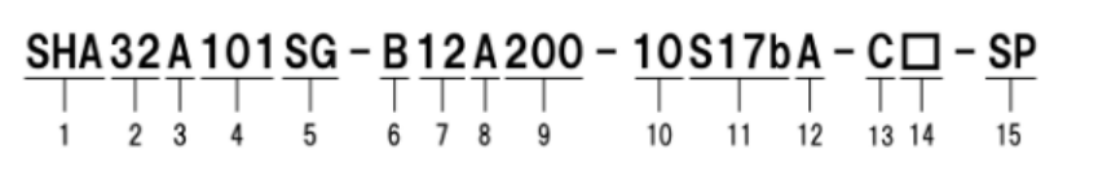

Harmonic Drive servo gear unit FHA-17C-100-E250-C

The Japanese Harmonic Drive DD motor FHA-17C-100-E250-C is mainly composed of four basic components: wave generator, flexible gear, flexible bearing, and rigid gear. The harmonic drive reducer is a kind of gear transmission in which the wave generator is assembled with a flexible bearing to make the flexible gear generate controllable elastic deformation and mesh with the rigid gear to transmit motion and power. The number of external teeth of the flexible gear is less than the number of internal teeth of the rigid gear. When the wave generator rotates, the external teeth of the flexible gear corresponding to the direction of the major axis precisely mesh into the internal teeth of the rigid gear.

Product Description

SHA series

Abstract

Specialties

HarmonicDrive ® Integrated AC servo actuator with specially designed flat AC servo motor

Hollow and flat structure

Absolute value encoder

SHA-SG: Compact shape with extra length

SHA-CG: For turntable use, improve the accuracy of output shaft surface vibration

1. Model name: AC servo actuator SHA series

2. Model:

SG type=20, 25, 32, 40, 45, 58, 65

HP type=25,32

CG type=20,25,32,40

3. Version symbols

4. HarmonicDrive ® Reduction ratio:

SG type=51,81101121161

HP type=11

CG type=50,80100120160

5. Type of reducer:

SG type=SHG series

HP type=HPF series

CG type=CSG series

6. Motor version symbol:

A=Models 58, 65

B=Models 25, 32, 40

C=Model 20

D=Model 45

7. Motor size:

● 08=Model 20

09=Model 25

12=Model 32

15=Model 40

16=Model 45

21=Models 58, 65

8. Brake:

● A=No brake

● B=With brake

9. Motor power supply voltage:

100=AC100V

200=AC200V

10. Encoder format:

10=symbol A format, transmission speed: 2.5Mbps, 1:1 connection

11. Encoder type and resolution:

S17b=17bit absolute encoder 131072 pulses/rotation

12. Encoder phase angle:

The phase difference A between the U-phase induced voltage of the motor and the absolute origin is 0 degrees

13 connector specifications:

● C=With standard connectors

● N=No connector

D=With special connectors

14. Optional symbols:

L=Near Origin&End Limit Sensor

Y=Cable side exit

● V=With bracket (CG type only)

● S=Output shaft 1 rotation absolute value specification (CG type only)

● No entry=standard product

SP=non-standard product