English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

Harmonic Drive FHA-8C-100-E200-C

The Harmonic Drive FHA-8C-100-E200-C micro workbench harmonic drive can generate radial elastic deformation with an external-toothed flexible wheel, and includes a wave generator installed inside the flexible wheel, elliptical in shape with a flexible roller bearing on the outer ring.

Product Description

SHA series

Abstract

The workbench that moves longitudinally and transversely generally comes equipped with a coordinate device. Commonly used methods for adjusting positions include manual adjustment with graduated handwheels. With increasing demands for machining precision, optical coordinate reading devices, digital readout magnetic scales, and other devices are more frequently employed.

In recent years, with advancements in technology and the development of CNC (Computer Numerical Control) capabilities in machines like the Harmonic Drive FHA-8C-100-E200-C, there have been developments in three-coordinate servo-controlled and five-coordinate CNC EDM (Electrical Discharge Machining) machines. These machines can control spindle and worktable rotation movements along with three-axis servo control. Some machines also feature automatic tool electrode changers.

The spindle head is a critical component in EDM machines, serving as the actuating mechanism in automatic adjustment systems. Its requirements include a simple structure, short transmission chain, minimal transmission clearance, low thermal deformation, sufficient precision, and stiffness to accommodate the demands of automatic adjustment systems. The spindle head primarily consists of feed systems, anti-twist guiding mechanisms, electrode clamping, and adjustment components. Common types of spindle heads used with the Harmonic Drive FHA-8C-100-E200-C include electro-hydraulic and electro-mechanical types.

Electro-hydraulic spindle heads typically come in two structures: one with a fixed hydraulic cylinder where the piston moves with the spindle vertically, and another where the piston is fixed and the hydraulic cylinder body moves with the spindle vertically. The former has a simple structure but lower rigidity, with sliding friction in the spindle guiding parts leading to reduced sensitivity.

Specialties

HarmonicDrive ® Integrated AC servo actuator with specially designed flat AC servo motor

Hollow and flat structure

Absolute value encoder

SHA-SG: Compact shape with extra length

SHA-CG: For turntable use, improve the accuracy of output shaft surface vibration

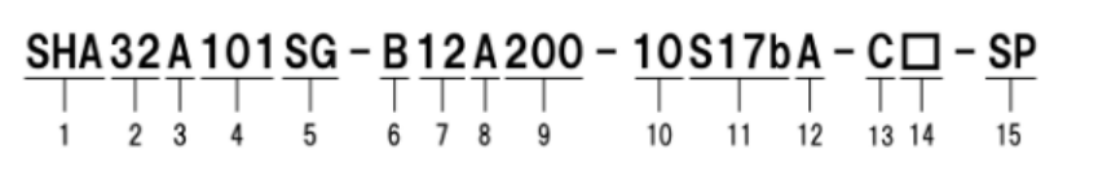

1. Model name: AC servo actuator SHA series

2. Model:

SG type=20, 25, 32, 40, 45, 58, 65

HP type=25,32

CG type=20,25,32,40

3. Version symbols

4. HarmonicDrive ® Reduction ratio:

SG type=51,81101121161

HP type=11

CG type=50,80100120160

5. Type of reducer:

SG type=SHG series

HP type=HPF series

CG type=CSG series

6. Motor version symbol:

A=Models 58, 65

B=Models 25, 32, 40

C=Model 20

D=Model 45

7. Motor size:

● 08=Model 20

09=Model 25

12=Model 32

15=Model 40

16=Model 45

21=Models 58, 65

8. Brake:

● A=No brake

● B=With brake

9. Motor power supply voltage:

100=AC100V

200=AC200V

10. Encoder format:

10=symbol A format, transmission speed: 2.5Mbps, 1:1 connection

11. Encoder type and resolution:

S17b=17bit absolute encoder 131072 pulses/rotation

12. Encoder phase angle:

The phase difference A between the U-phase induced voltage of the motor and the absolute origin is 0 degrees

13 connector specifications:

● C=With standard connectors

● N=No connector

D=With special connectors

14. Optional symbols:

L=Near Origin&End Limit Sensor

Y=Cable side exit

● V=With bracket (CG type only)

● S=Output shaft 1 rotation absolute value specification (CG type only)

● No entry=standard product

SP=non-standard product