Application Status of Harmonic Drive Harmonic Reducer in Collaborative Robot Market

Application Status of Harmonic Drive Harmonic Reducer in Collaborative Robot Market

With the rapid development of intelligent manufacturing and Industry 4.0, collaborative robots, as an important member of the emerging field, are gradually occupying a pivotal position in the manufacturing industry. In this transformation process, Harmonic Drive harmonic reducer plays an irreplaceable role in the collaborative robot market with its excellent performance and wide application advantages.

1. The rise and demand of collaborative robots

As a robot that can safely interact with humans in the same workspace, the market demand for collaborative robots has continued to grow in recent years. They not only improve production efficiency, but also enhance the flexibility and safety of the working environment. However, the efficient operation of collaborative robots cannot be separated from the support of core components, among which harmonic reducer is one of the keys.

2. The unique advantages of Harmonic Drive harmonic reducer

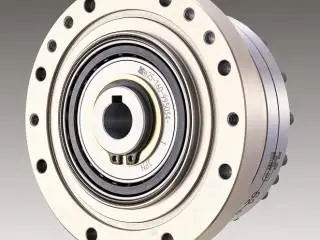

Harmonic Drive harmonic reducer has become an ideal choice for collaborative robots with its high precision, high rigidity, high torque capacity, no backlash and compact and lightweight design. These characteristics enable harmonic reducers to achieve precise position control and high-speed movement in a limited space, thus meeting the high requirements of collaborative robots for flexibility and precision.

3. Specific applications in collaborative robots

3.1. Joint drive: The joints of collaborative robots are the key parts for them to achieve flexible movement. Harmonic Drive harmonic reducers are widely used in the joints of robots due to their high reduction ratio and precise control. Through the precise transmission of harmonic reducers, collaborative robots can achieve more precise and smooth movements, thereby completing various complex operating tasks.

3.2. Power transmission: Harmonic Drive harmonic reducers also play an important role in the power transmission system of collaborative robots. They can transmit power stably to ensure that the robot maintains an efficient and stable operating state during work. At the same time, the backlash-free characteristics of harmonic reducers reduce energy loss during transmission and improve the efficiency of the overall system.

3.3. Load capacity: Collaborative robots often need to carry a certain load to work. Harmonic Drive harmonic reducers, with their high torque capacity, can withstand large loads and shocks, ensuring that the robot can operate stably under various working conditions.

4. Market Outlook

With the continuous expansion of the collaborative robot market and the continuous advancement of technology, the performance requirements for harmonic reducers are also increasing. As a leading company in the field of harmonic reducers, Harmonic Drive will continue to invest in research and development and launch more high-performance, high-precision, and high-reliability products to meet market demand. In the future, the application of Harmonic Drive harmonic reducers in the collaborative robot market will be more extensive and in-depth, contributing greater strength to the development of intelligent manufacturing and Industry 4.0.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски

A Giant Eye Exploring the Origins of the Universe: The Optical Marvel of the Subaru Telescope

As an international collaborative project led by the National Astronomical Observatory of Japan, its name comes from the Pleiades (M45), symbolizing the collective wisdom and global collaboration of the Japanese astronomical community.

Read MoreSpace Industry: HarmonicDrive® and Humanity's First Round Trip to the Asteroid Belt

The space industry, as a cutting-edge field for human exploration of the universe and development of space resources, is developing at an unprecedented pace.

Read MoreHarmonic Drives: The "Space Joints" of NASA's Perseverance Rover's Robotic Arm

In February 2021, NASA's Perseverance rover successfully landed on the Martian surface, marking a new era in human exploration of Mars. One of the most striking technological highlights of this 1025-kilogram "Mars scientist" is its robotic arm system—five Harmonic Drive® units serve as the core transmission components, ensuring the precise operation of scientific instruments in the extreme Martian environment.

Read More